2, Capacitive Touchscreen Technology. The capacitive touchscreen technology is the most popular and durable touchscreen technology used in most consumer electronics today. As the name suggests, it detects the location of touching point by measuring capacitance. There are two types of capacitive touchscreens: surface-capacitive touchscreen and projected-capacitive touchscreen. Both consist of a glass panel with conductive material, Indium Tin Oxide (ITO), coated on the bottom surface while the top surface being the one touched by our fingers. Since there is no mechanical bending involved, it is more durable than the resistive touchscreen. It is also more transparent, allowing more light from the monitor beneath to be transmitted.

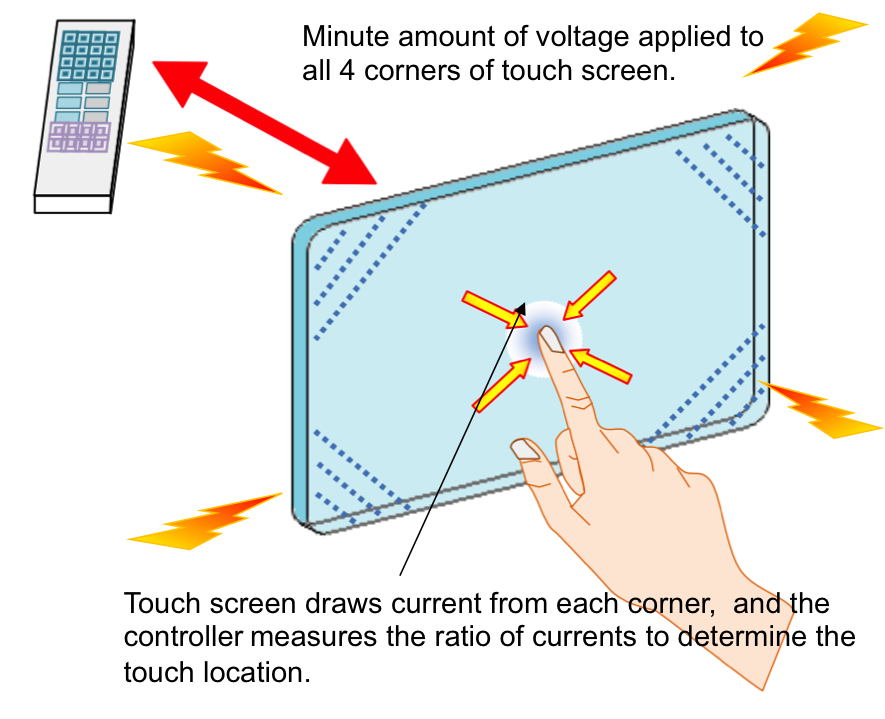

Surface-Capacitive touchscreens. In this technique, the bottom surface of the glass screen is coated uniformaly with conducting ITO. When a finger touches the top surface of the glass, a capacitor is formed between the bottom ITO (acting as one electrode), the glass (insulator) and finger (top electrode since human body conducts electricity). A small voltage is applied to this layer, resulting in a uniform electric field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. Because of the sheet resistance of the ITO layer, each corner is measured to have a different effective capacitance. The sensor’s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel: the larger the change in capacitance, the closer the touch is to that corner. With no moving parts, it is moderately durable, but has low resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. Therefore, it is most often used in simple applications such as industrial controls and interactive kiosks.

Figure 3, Surface-capacitive touchscreen measures the difference in capacitances from the four corners of the bottom ITO layer through the insulating glass to the fingertip.

Figure 3, Surface-capacitive touchscreen measures the difference in capacitances from the four corners of the bottom ITO layer through the insulating glass to the fingertip.

Pros and Cons: The surface capacitive touchscreen is moderately durable and requires calibration during manufacture. Since a conductive material is required to form the capacitor with the glass and bottom ITO layer, one can not operate the screen wiring a normal glove (ultra-thin gloves and specially designed ones with conducting threads embeded are ok) or using a passive stylus.

In the Projected-Capacitive Touchscreen technology, the bottom conductive ITO layer is etched to form a grid of multiple horizontal and vertical electrodes. It involves sensing along both the X and Y axis using these etched ITO lines. There are two types of projected capacitive touchscreen: Self Capacitance and Mutual Capacitance.

Figure 4, Schematic of a self-capacitance touchscreen.

Self-capacitance touchscreen is similiar to surface-capacitance ones in that the finger, the glass and bottom conducting ITO together form the capacitor. The difference is that, in self-capacitance touchscreen, the bottom ITO is patterned into X-Y grid as shown in Figure 4. The columns and rows operate independently. To locate the touch point, current senses the capacitive load of a finger on each column or row independently.

Figure 5, Schematic of a mutual-capacitive touchscreen.

Mutual capacitive sensors have a capacitor at each intersection of each row and each column. This is done by adding an additional dielectric layer between the two sets of electrodes. A 20-by-20 array, for example, would have 400 independent capacitors. During sensing, a voltage is applied to each electrode of the rows or columns. Bringing a finger or conductive stylus near the surface of the sensor changes the local electric field which reduces the mutual capacitance. The capacitance change at every individual junction on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers can be accurately tracked at the same time.

Capacitive touchscreens allow operation with no direct contact, so that the conducting layers are protected by the overlaying glass. They can operate under screen protectors, or behind weather and vandal-proof glass. This makes them more robust than resistive touchscreen technology. Depending on the implementation, a stylus can be used instead of or in addition to a finger. This is common with point of sale devices that require signature capture. The major issue with capacitive touchscreens is that a conducting object such as human finger is needed. Wearing gloves causes the screen non-responsive, unless the gloves are very think or contain conducting threads. Conductive smudges and similar interference on the panel surface can interfere with the performance. Such conductive smudges come mostly from sticky or sweaty finger tips, especially in high humidity environments.